Class N autoclaves

Class N autoclaves are compact and they are for sterilizing simple materials. The letter “N” stands for “naked solid products”. Therefore, these autoclaves cannot be used to sterilize textiles, porous loads, hollow items or even products in pouches, as the cycles do not have the right characteristics to pass specific physical tests. Another potential weakness of these machines is that the required steam penetration cannot be guaranteed. Among other things, it is dependent on the creation of a vacuum at the start, which is not obligatory in these machines.

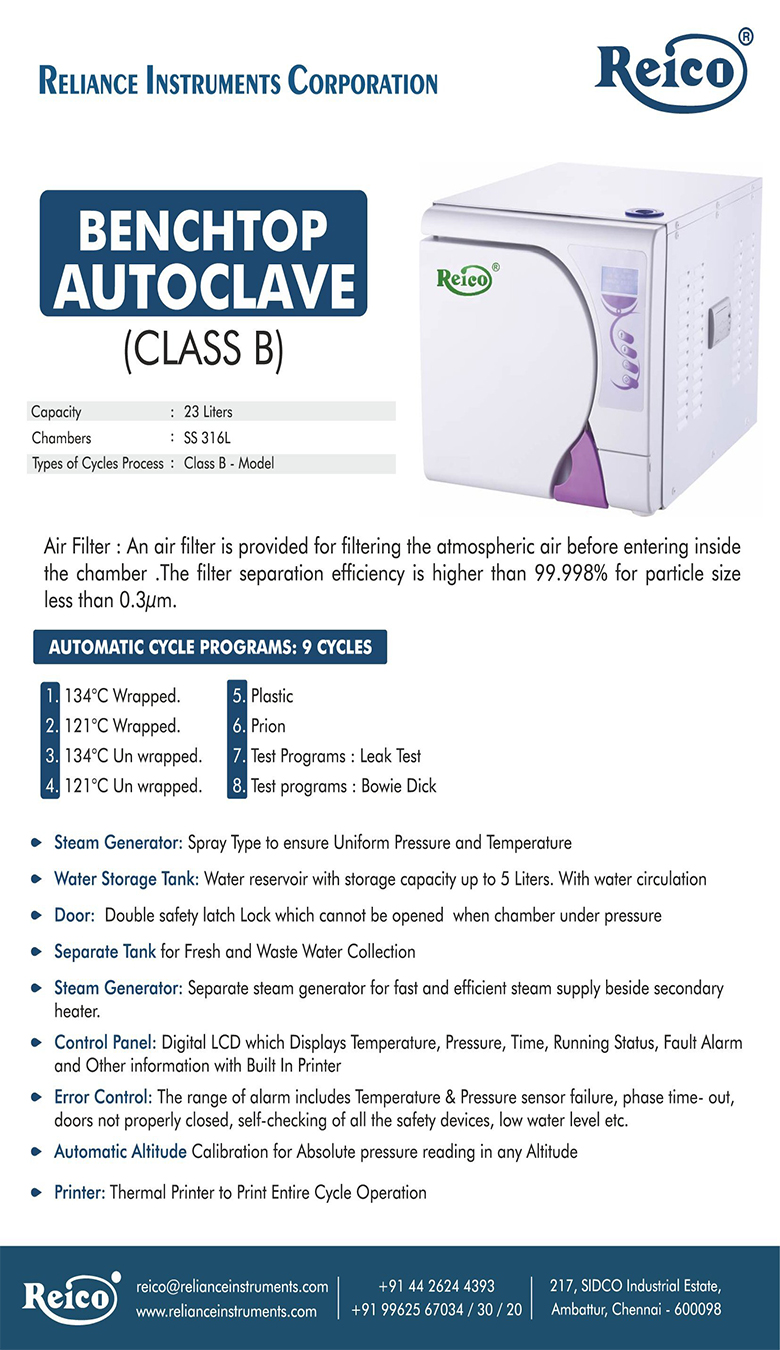

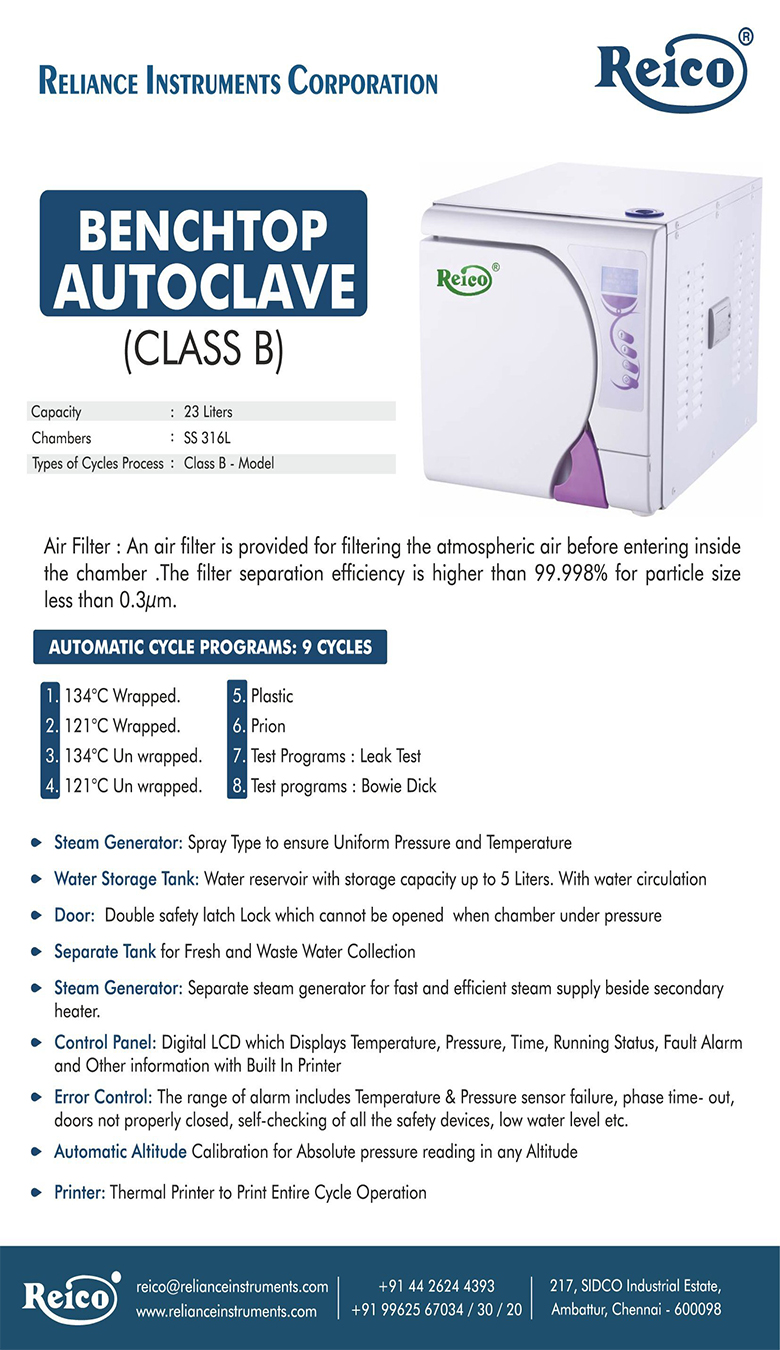

Class B autoclaves

Class B autoclaves are compact but their performance levels are comparable to those of the largest machines in hospitals. The letter “B” stands for “big small sterilizers”, because they are small machines that offer big performance. Any type of load can be sterilized in a Class B autoclave. This includes porous materials, products in pouches, textiles and hollow items such as wands, turbines and tips. The applicable standard for equipment of this kind is EN 13060, which is specifically dedicated to small steam sterilizers (i.e. machines with a sterilization chamber that is smaller than the sterilization unit). The standard distinguishes between sterilization cycles on the basis of the materials being sterilized (solid loads, type A solid loads with hollow sections and type B solid loads with hollow sections).

Class S autoclaves

Finally, Type S covers all of the other types of autoclaves. Essentially, it is an intermediate class between Type N and Type B autoclaves and the characteristics are not defined by any standards. It simply depends how they are made. Only the manufacturers can provide details of their performance capabilities, which are established by specific tests.

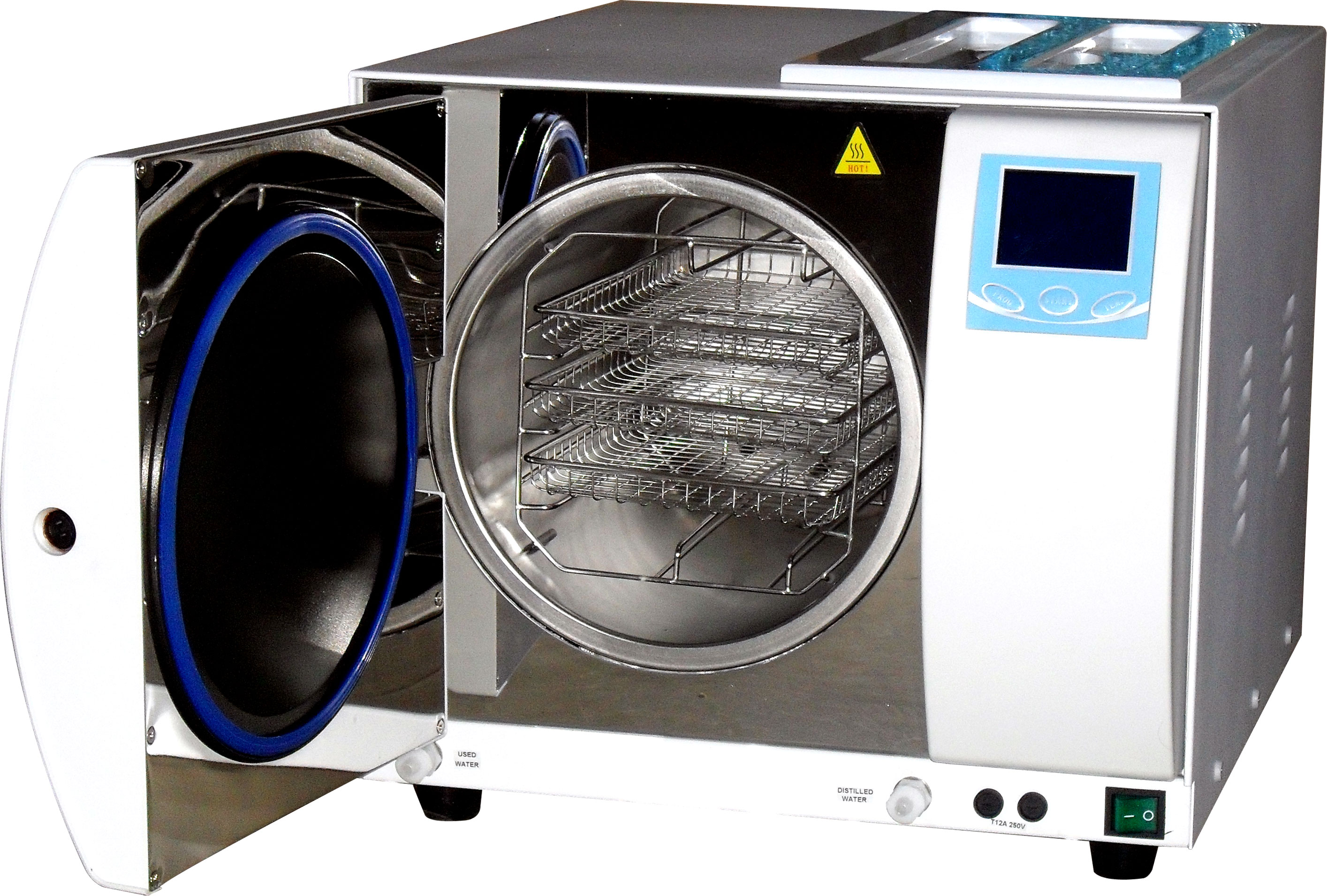

Therefore, the most suitable machine for a dental practice is a Class B autoclave, because it offers greater flexibility and is suitable for a wide range of settings. Although they are small, Class B autoclaves can offer outstanding performance, unbeatable efficiency and the highest possible safety standards. Their noteworthy strengths include easy handling thanks to their ergonomic designs and energy savings due to their low power consumption. User-friendly Class B autoclaves are the epitome of hygiene and safety, as well as practicality and comfort.

WHAT IS AN AUTOCLAVE?

Autoclaves are also known as steam sterilizers, and are typically used for healthcare or industrial applications. An autoclave is a machine that uses steam under pressure to kill harmful bacteria, viruses, fungi, and spores on items that are placed inside a pressure vessel. The items are heated to an appropriate sterilization temperature for a given amount of time. The moisture in the steam efficiently transfers heat to the items to destroy the protein structure of the bacteria and spores.

In healthcare, the term "autoclave" is typically used as the nomenclature to describe a Steam Sterilizer. ANSI/AAMI4, which provide standards and guidelines for the processing of medical devices, refers to autoclaves for healthcare specifically as Steam Sterilizers.

HOW DOES AN AUTOCLAVE WORK?

Autoclaves are commonly used in healthcare settings to sterilize medical devices. The items to be sterilized are placed inside a pressure vessel, commonly referred to as the chamber. Three factors are critical to ensuring successful steam sterilization in an autoclave: time, temperature and steam quality.

To meet these requirements there are three phases to the autoclave process:

Conditioning Phase (C): Air inhibits sterilization and must be removed from the chamber during the first phase of the sterilization cycle known as conditioning. In dynamic air removal-type steam sterilizers, the air can be removed from the chamber using a vacuum system. It can also be removed without a vacuum system using a series of steam flushes and pressure pulses. Gravity-type sterilizers use steam to displace the air in the chamber and force the air down the sterilizer drain.

Exposure Phase (S): After the air is removed, the sterilizer drain closes and steam is continuously admitted into the chamber, rapidly increasing the pressure and temperature inside to a predetermined level. The cycle enters the exposure phase and items are held at the sterilization temperature for a fixed amount of time required to sterilize them.

Exhaust Phase (E): During the final phase of the cycle, exhaust, the sterilizer drain is opened and steam is removed, depressurizing the vessel and allowing the items in the load to dry.

Quality steam is vital to a successful autoclave sterilization process. The steam used for sterilization should be composed of 97% steam (vapor) and 3% moisture (liquid water). This ratio is recommended for the most efficient heat transfer. When the steam moisture content is less than 3%, the steam is described as superheated (or dry). Superheated steam is too dry for efficient heat transfer and is ineffective for steam sterilization.

WHAT IS THE AUTOCLAVE TEMPERATURE RANGE?

Commonly recommended temperatures for steam sterilization are 250° F (121° C), 270°F (132°C) or 275°F (135° C). To kill any microorganisms present, the items being sterilized must be exposed to these temperatures for the minimum time recommended by the manufacturer of the device being processed.

WHAT IS THE AUTOCLAVE CYCLE TIME FRAME?

The exposure time is the time necessary to sterilize the device and does not include the entire cycle time. There is a time/temperature relationship for proper steam sterilization which has been developed by scientific testing and is used in all sterilization methods to create what is known as the total exposure phase. Exposure periods for steam sterilization vary with size, shape, weight, density and material composition of the device being sterilized, among other factors.

HOW BIG IS AN AUTOCLAVE?

The size of the sterilizer will vary based on the capacity needed for the area where the autoclave will be used. For example, in a dental office a small autoclave may simply sit on the countertop where the equipment only needs to sterilize small packs of instruments. An immediate-use small sterilizer is typically needed near an operating room, and may only need to process 1-3 trays of instruments at a time. Most healthcare facilities, however, have medium or large autoclave machines in their Sterile Processing Department (SPD) which can process 15-20 trays of instruments per cycle or even up to 625 lbs of instruments per cycle depending on size.

Industrial sized autoclaves for manufacturing processes can be very large, some comparable to the size of a semi-truck or airplane.

Autoclave Manufacturers in Chennai

Types and classes of autoclaves

Class N autoclave. Class N autoclave is the lowest class device. ...

Class S autoclave. Class S autoclave is an intermediate class between N and B. ...

Class B autoclave. Class B autoclaves are the most advanced steam sterilizers.

Autoclave Manufacturers in Tamil Nadu

The two basic types of steam sterilizers (autoclaves) are the gravity displacement autoclave and the high-speed prevacuum sterilizer.

Autoclave Manufacturers in Coimbatore

Autoclaves are commonly used in healthcare settings to sterilize medical devices. The items to be sterilized are placed inside a pressure vessel, commonly referred to as the chamber. Three factors are critical to ensuring successful steam sterilization in an autoclave: time, temperature and steam quality.

Autoclave Manufacturers in Mumbai

Class B autoclaves utilize a vacuum pump to completely remove air from the chamber, which enables steam to better penetrate the load. Class N autoclaves use steam from a boiler or generator to create downward displacement, which pushes air out of the chamber.

Autoclave Manufacturers in Kolkata

Autoclaving is better than boiling because it can generate much higher temperatures where microbes that are boiling-resistant cannot survive. Steam sterilisation is highly efficient, making it one of the most reliable forms of sterilisation. Autoclaving can be used on various instruments.

Autoclave Manufacturers in Delhi

The best requirement for autoclaves is distilled water. Distilled water is deionized water or pure water which has undergone a process of distillation to remove impurities in the water and provide the cleanest water possible.

Hospital Autoclave Manufacturers in Chennai

Autoclaves are commonly used in healthcare settings to sterilize medical devices. The items to be sterilized are placed inside a pressure vessel, commonly referred to as the chamber. Three factors are critical to ensuring successful steam sterilization in an autoclave: time, temperature and steam quality.

Hospital Autoclave Manufacturers in Coimbatore

There are many different aspects that can be used as a basis for the categorization of the different types of autoclaves, and some of these aspects may overlap with each other. In most cases, steam sterilizers can be differentiated by:

function

class

size (capacity)

Hospital Autoclave Manufacturers in Tamil Nadu

Different types of autoclaves categorized by function: All autoclaves use high-temperature and high-pressure steam to sterilize medical equipment and waste. Their function indicates how they should be loaded, and how they force in the steam in their chamber to sterilize the instruments inside.

Hospital Autoclave Manufacturers in Mumbai

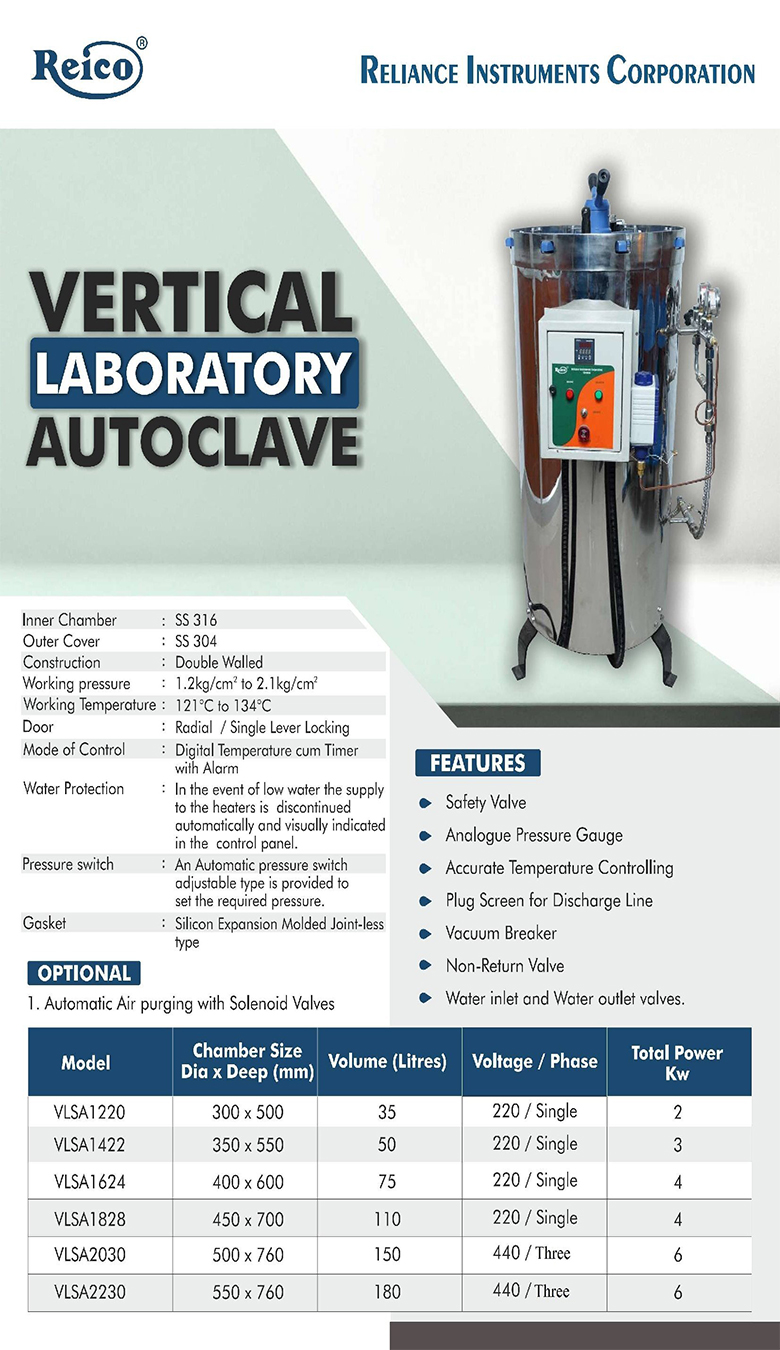

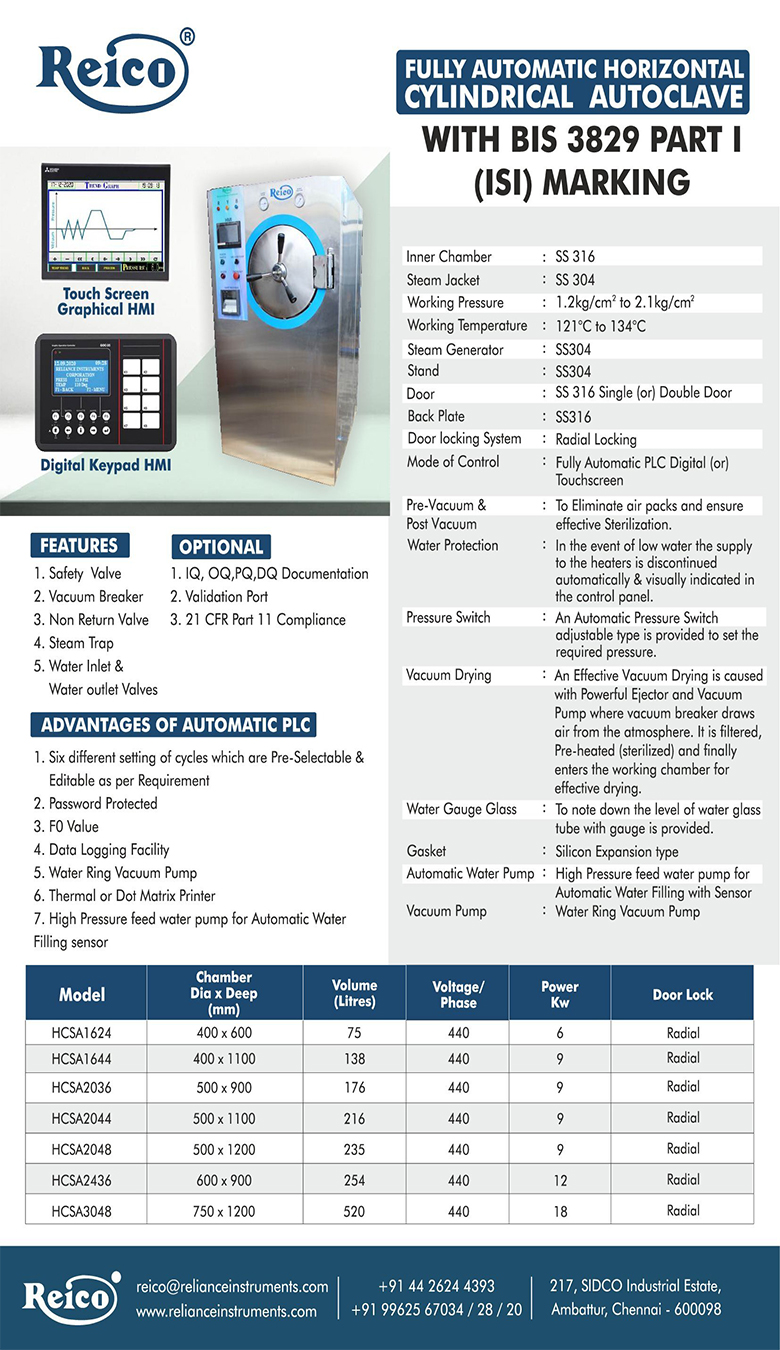

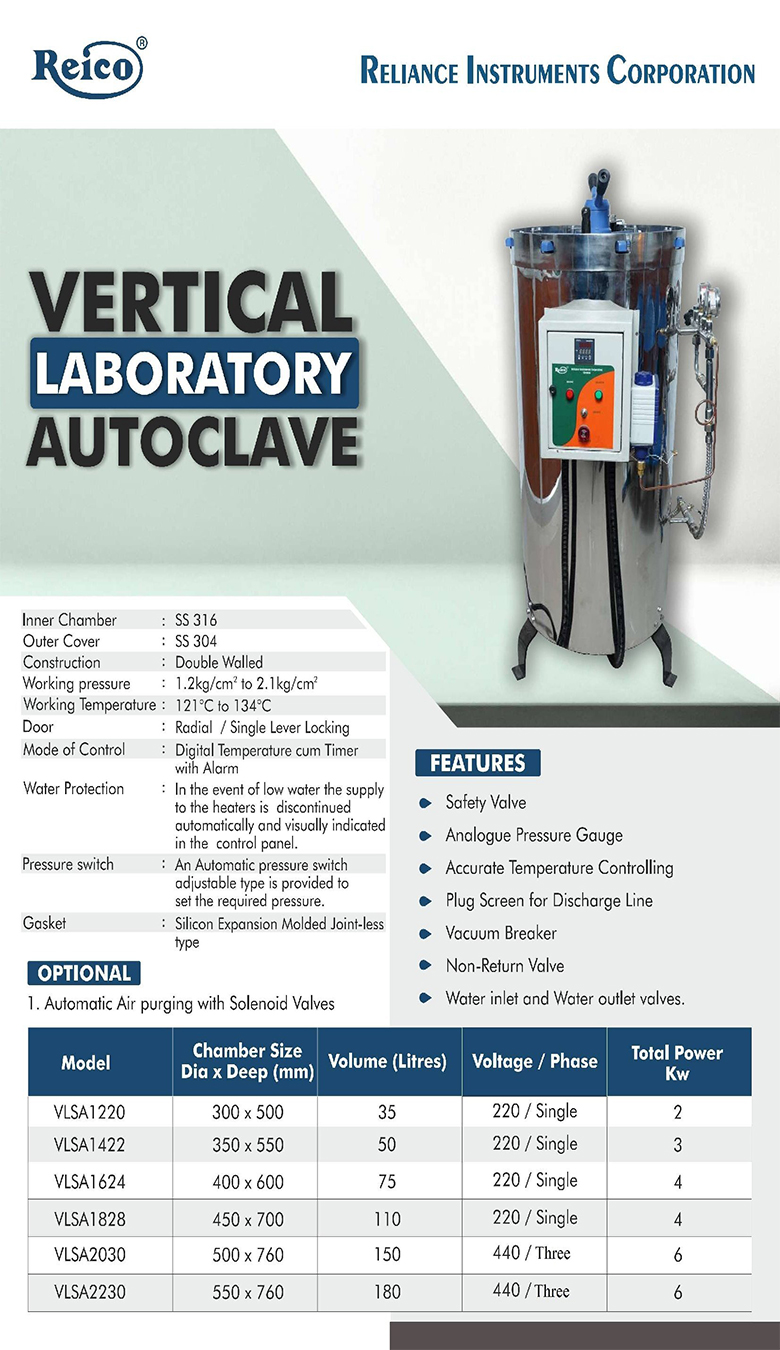

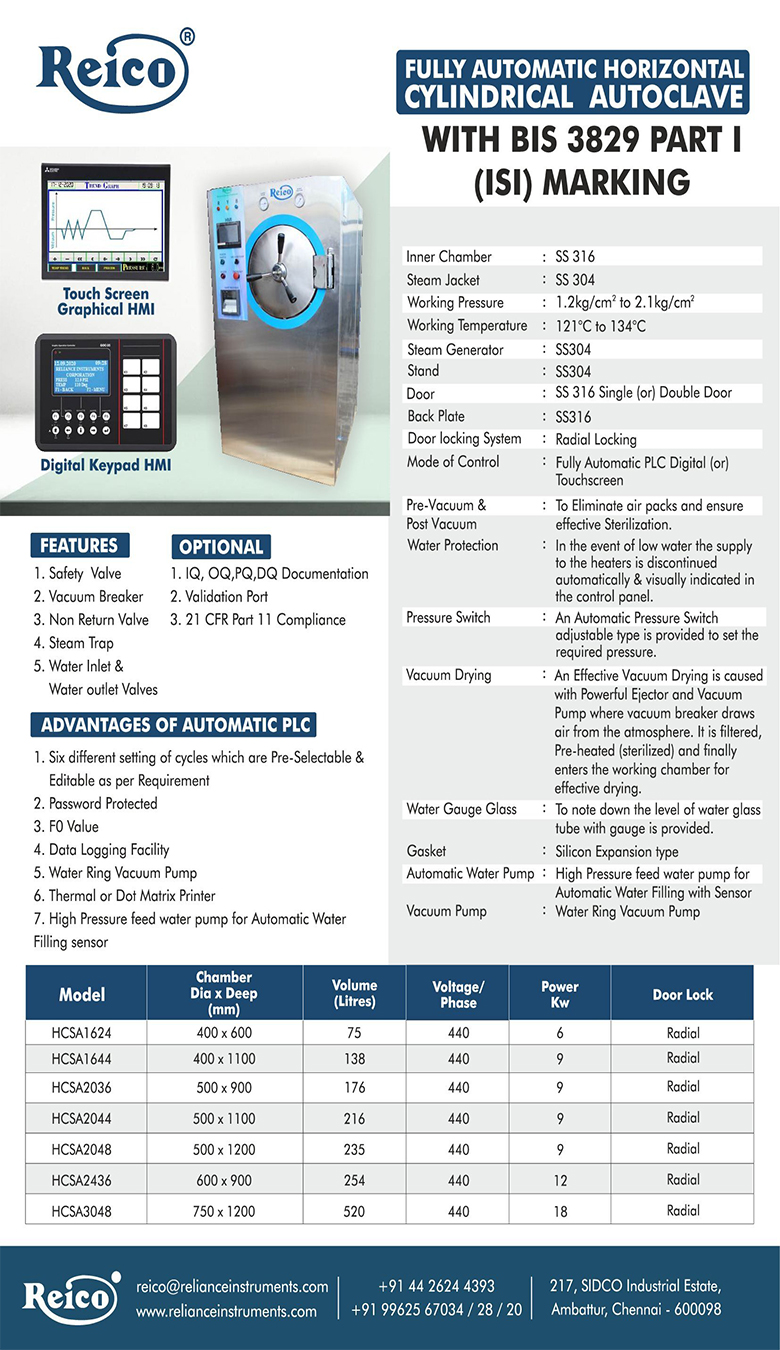

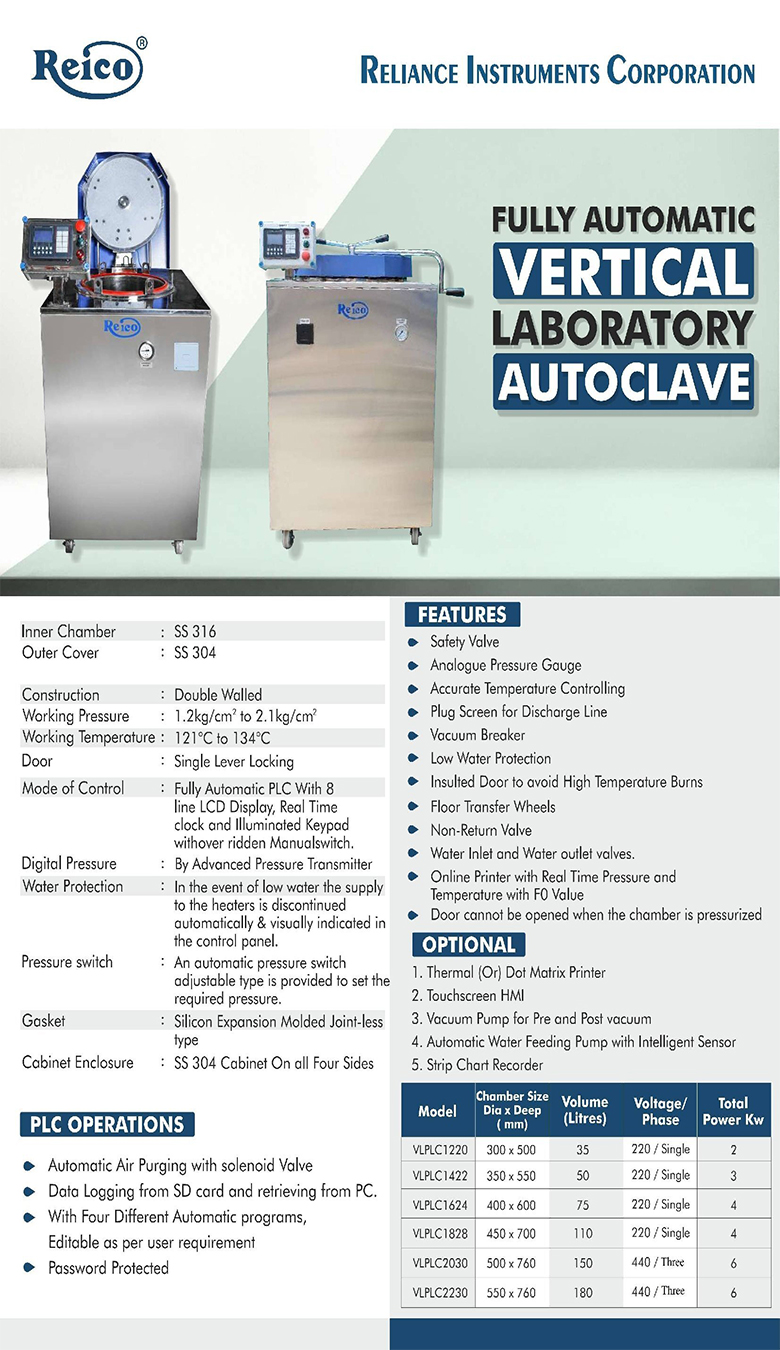

Vertical autoclaves:

These types of autoclaves are loaded by opening their top lid. Especially suited for laboratory use or in smaller clinics with cramped spaces. As such, they also have a smaller capacity chamber.

Hospital Autoclave Manufacturers in Kolkata

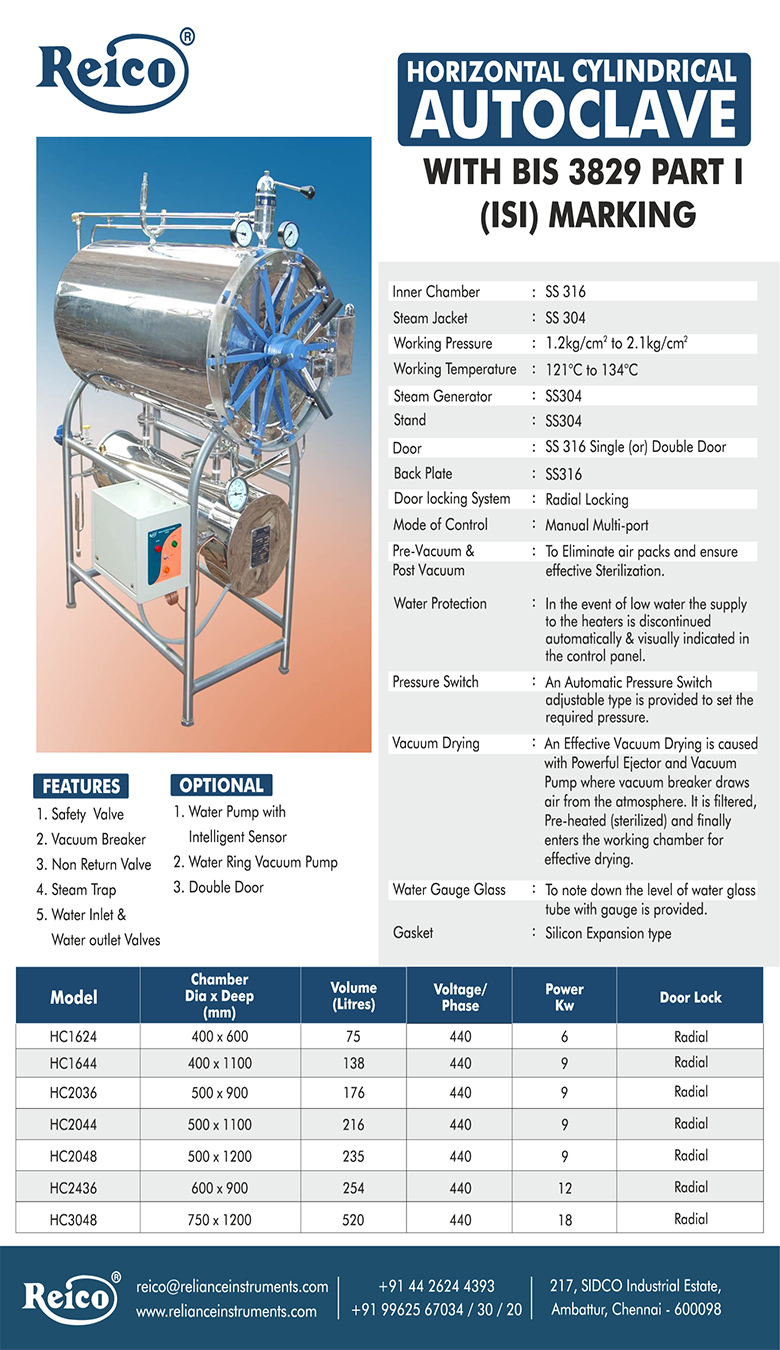

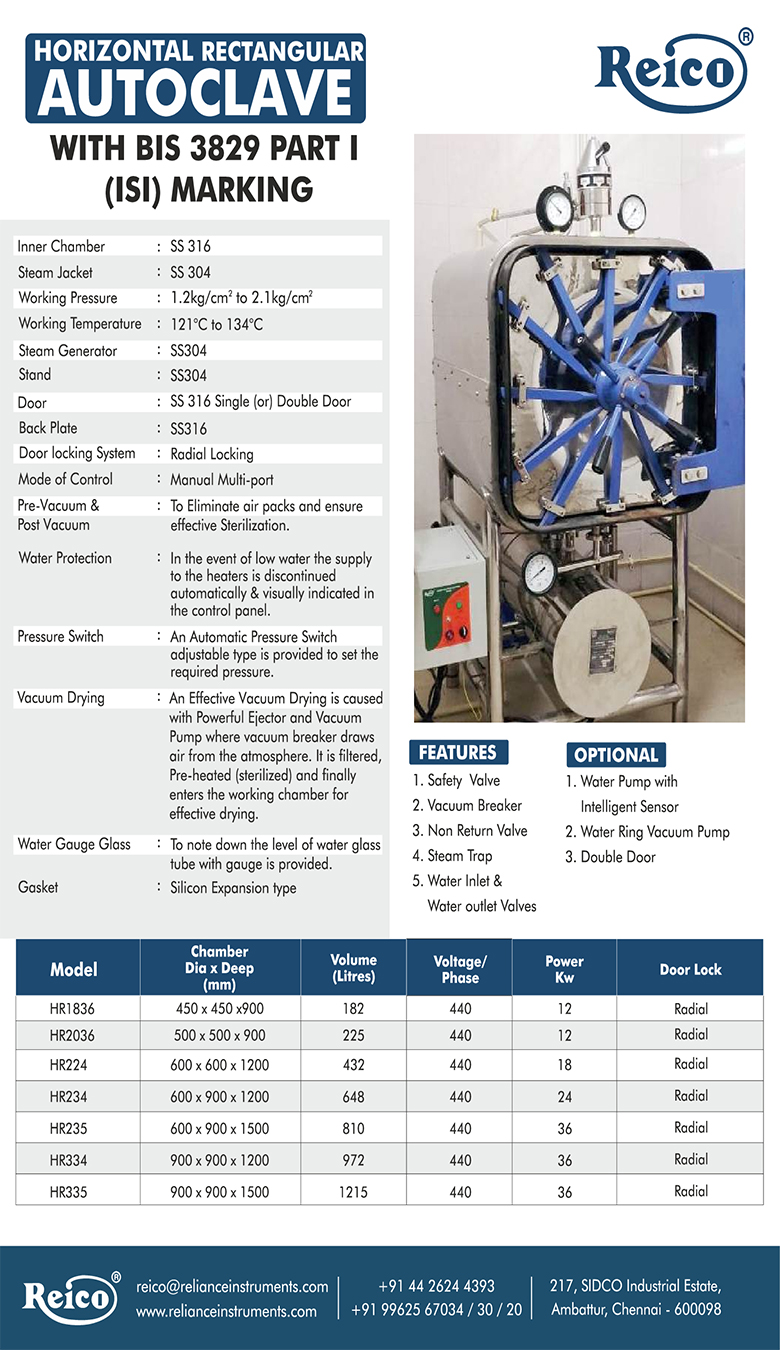

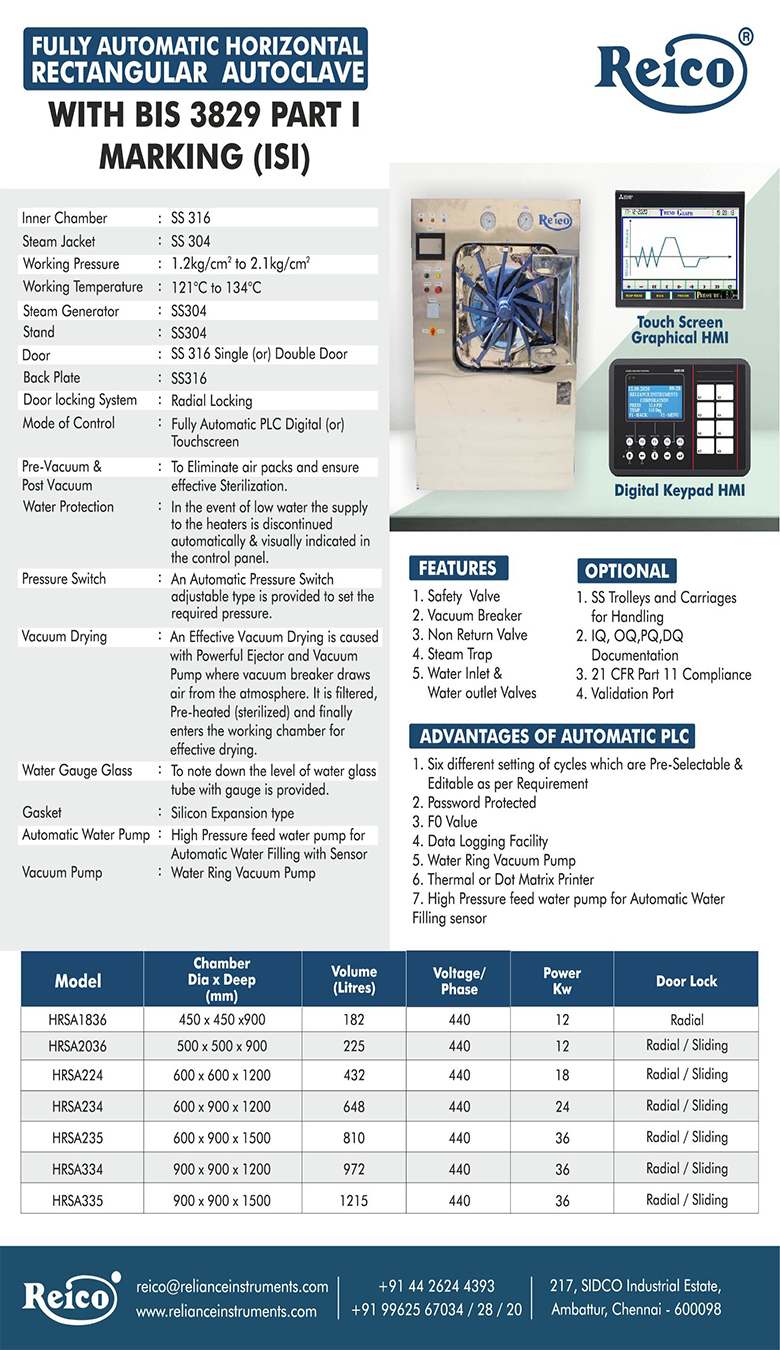

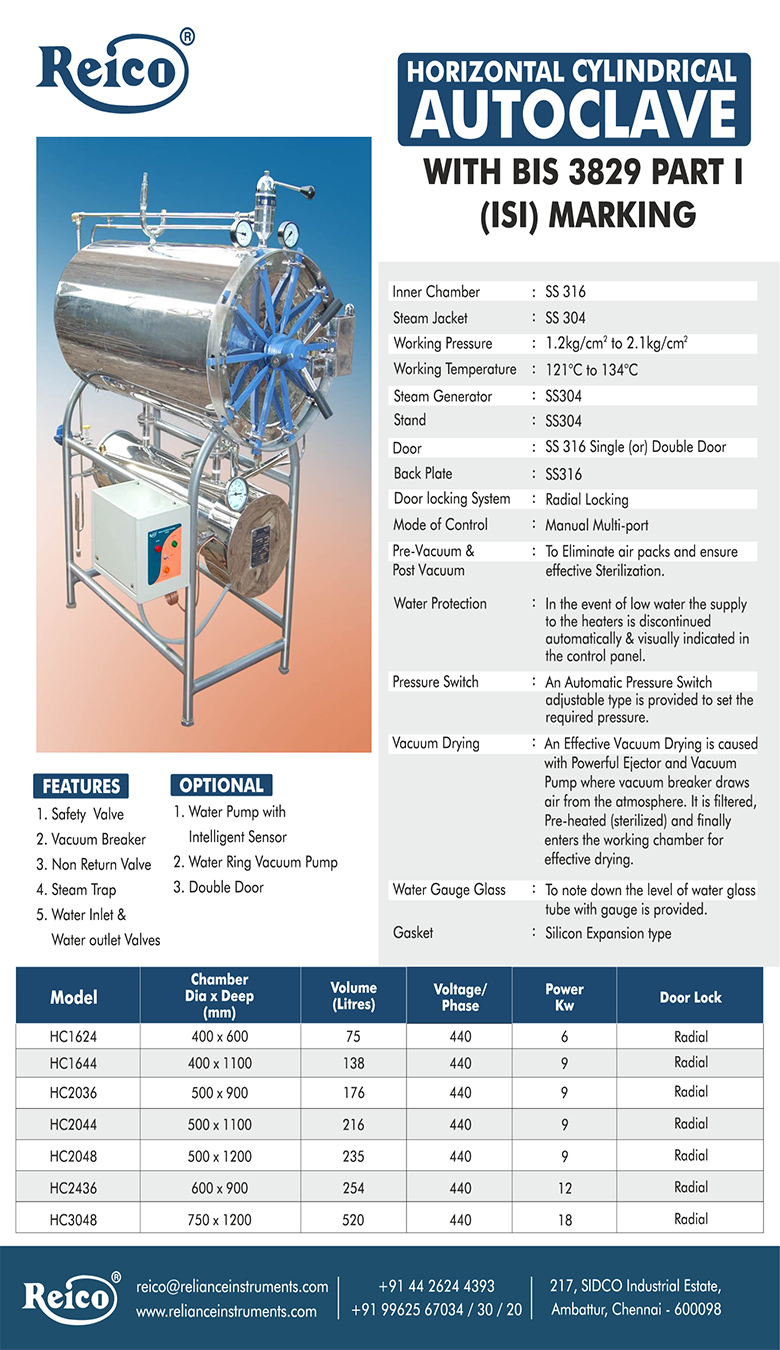

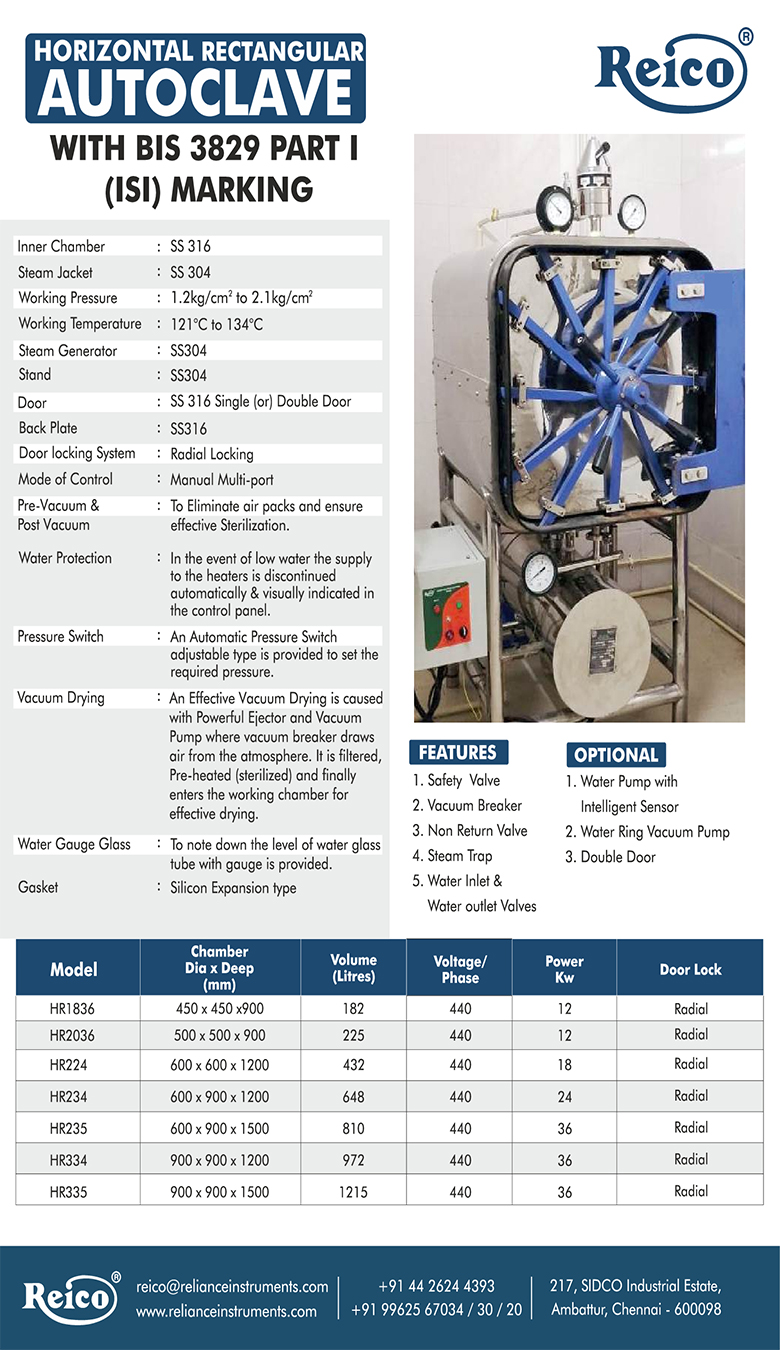

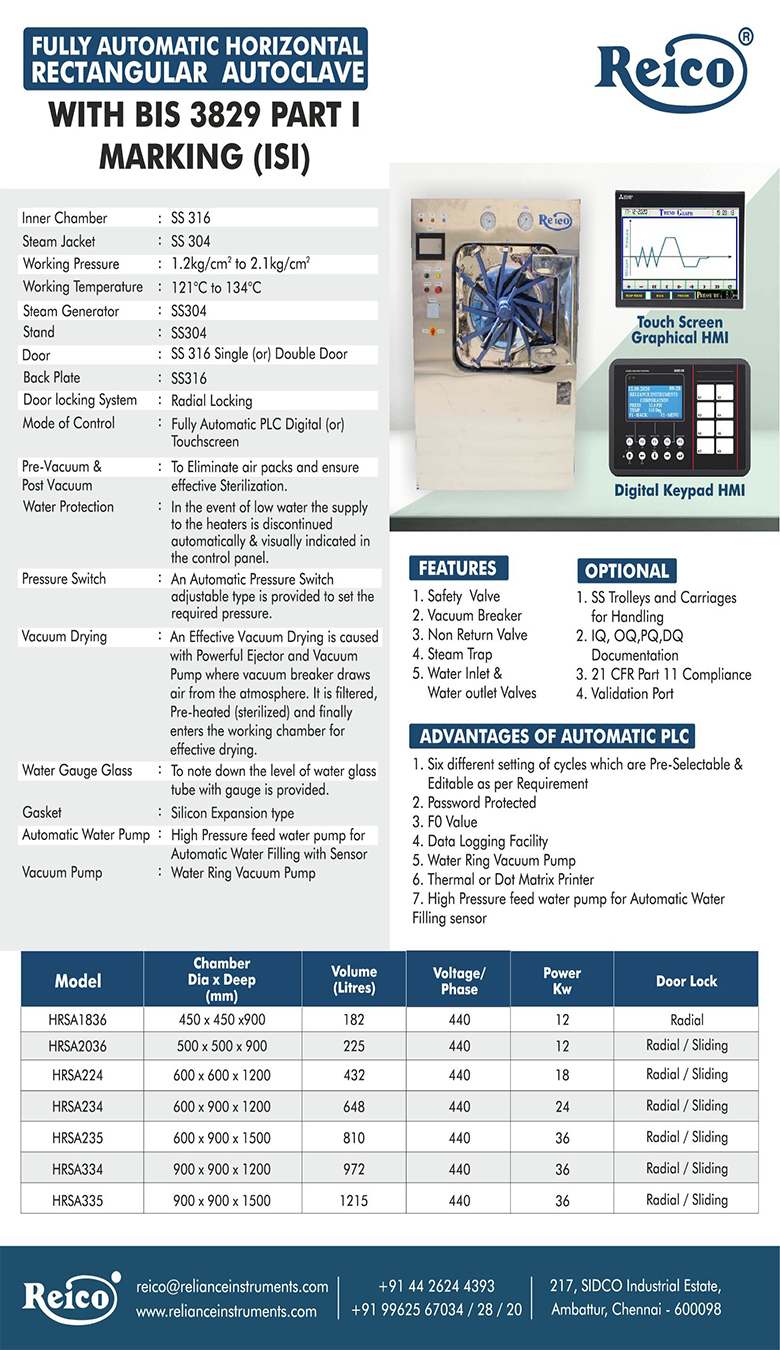

Horizontal autoclaves:

Front-loading steam sterilizers with a larger capacity chamber. When available space is not an issue, and you need to treat many loads a day, this one is exceptional for reducing the strain on medical staff.

Hospital Autoclave Manufacturers in Delhi

Gravity displacement autoclaves:

One of the most common type of autoclave that relies on using dense steam to force out the air from the machine’s chamber. They are suitable for the treatment of basic loads like flat surgical tools and certain types of biohazardous waste but are not as versatile as prevacuum autoclaves.

Industrial Autoclave Manufacturers in Chennai

Pre-vacuum (prevac) autoclaves :

This type of autoclave uses a vacuum pump to remove all the air from the autoclave’s chamber, allowing for better steam penetration, and the sterilization of more materials and complex loads such as medical textile products, porous loads, larger pieces of equipment, and even objects made from high-density polyethylene like the syringes of sharps and pipette tips.

Industrial Autoclave Manufacturers in Tamil Nadu

Different types of autoclaves categorized by class:

A more clear-cut way of categorizing the different types of autoclave machines. A steam sterilizer’s class indicates how versatile it is: in other words, it shows what kind of loads can be treated with it.

Industrial Autoclave Manufacturers in Coimbatore

Class N autoclaves:

These are essentially simple, gravity displacement autoclaves that only remove a certain portion of the air inside the machine’s chamber. Designed for the treatment of simpler loads like flat medical tools.

Industrial Autoclave Manufacturers in Mumbai

Class S autoclaves:

Another type of gravity displacement autoclave that uses a wall of dense steam, but by repeating the process 3 times, it can actually extract all the air from the chamber, and as such, it can already treat bagged instruments and porous loads. Still less versatile and not as fast a class B autoclave though.

Industrial Autoclave Manufacturers in Kolkata

Class B autoclaves :

Premium pre-vacuum autoclaves that can sterilize the most materials and are also much faster at doing so by removing all the air from their chamber with a powerful vacuum pump. Some models make the best out of modern technology and operate with a completely automated process: this ease-of-use and effectiveness make them very attractive for all kinds of medical facilities.

Industrial Autoclave Manufacturers in Delhi

Different types of autoclaves categorized by size (capacity) :

Here is a categorization that is pretty straightforward, but it certainly does not make it less important to consider. Autoclave size is also a key factor that needs to be taken into account: the right choice here depends on the amount of waste your facility needs to be treated each day, as well as the amount of available space you have.

Automatic Autoclave Manufacturers in Chennai

Large steam sterilizers :

The capacity of these types of autoclaves usually ranges between 110 to 880 liters. Ideal for large medical facilities like hospitals that generate a notable amount of waste each day and needs to use a lot of medical tools and equipment to treat patients.

Automatic Autoclave Manufacturers in Tamil Nadu

Medium-sized steam sterilizers:

The capacity of these types of autoclaves usually ranges between 75 to 200 liters. An excellent choice for dental and other clinics, biotechnological applications, or for operating theaters in hospitals.

Automatic Autoclave Manufacturers in Coimbatore

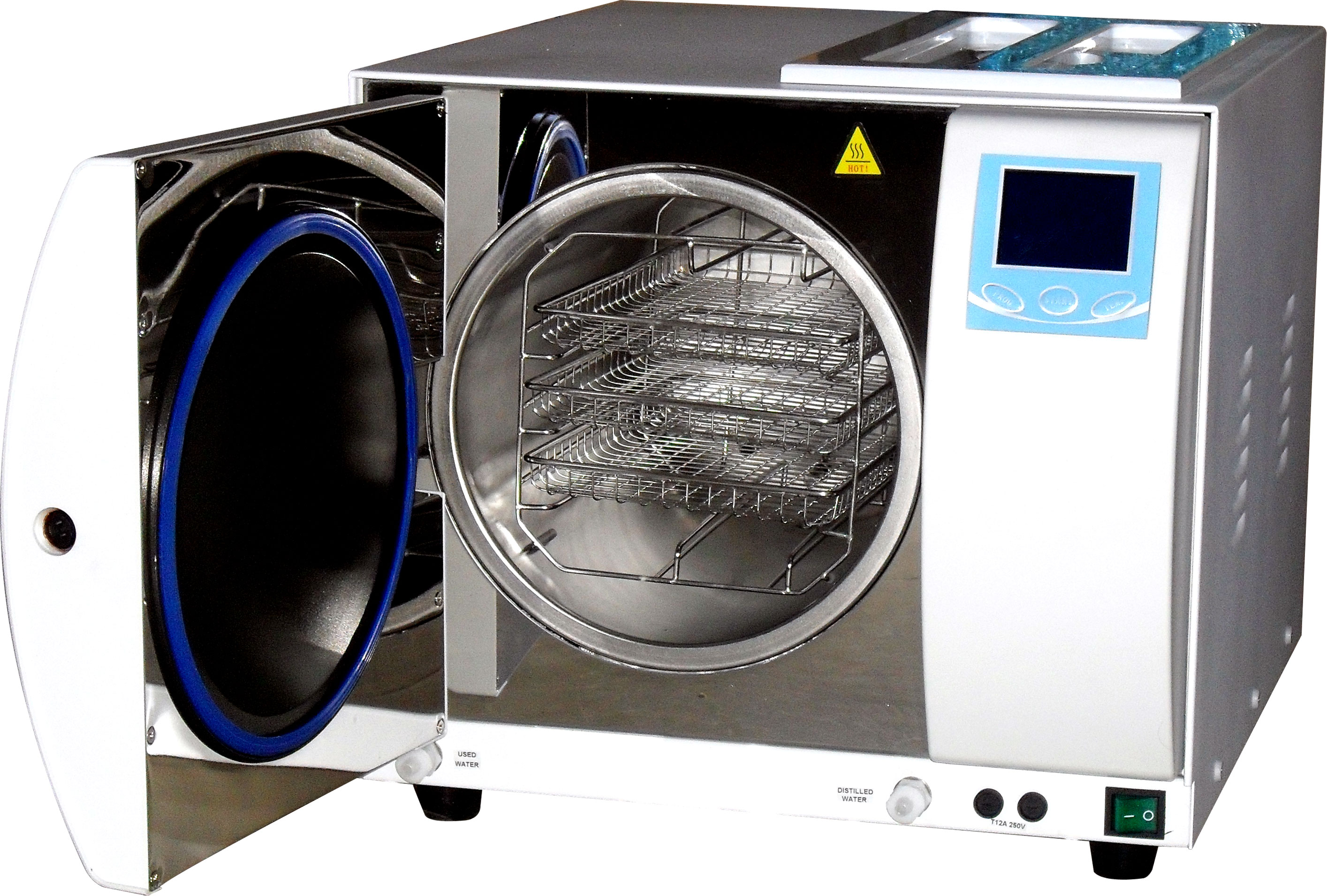

Small (benchtop) steam sterilizers:

The capacity of these types of autoclaves usually moves around 25 liters. These compact steam sterilizers are perfectly suited for smaller facilities with limited available space, and who do not need to sterilize as many medical tools each day.

Automatic Autoclave Manufacturers in Mumbai

Different types of autoclave machines available at Celitron – reliable and practical sterilization methods for medical facilities of all sizes

Automatic Autoclave Manufacturers in Kolkata

Regardless of size, all of Celitron’s steam sterilizers are quality pre-vacuum, class B autoclave types! They are all made of corrosion-resistant, high-quality 316L stainless steel, enabling them to handle all kinds of medical tools in the long term.

Automatic Autoclave Manufacturers in Delhi

They are also extremely easy to use thanks to their one-touch-operation: the entire steam sterilization process can be launched with the push of a button. Even the doors of the machines close automatically. Depending on the quantity of medical instruments and waste that you need sterilized, our autoclaves only need about 20 minutes to complete the process, including drying the load inside.

Vertical Autoclave Manufacturers in Chennai

Our steam sterilizers also come with extra safety features: until pressure and temperature levels are still too high inside their chamber, their chamber door cannot be opened, which helps protect medical staff from unwanted incidents.

Vertical Autoclave Manufacturers in Tamil Nadu

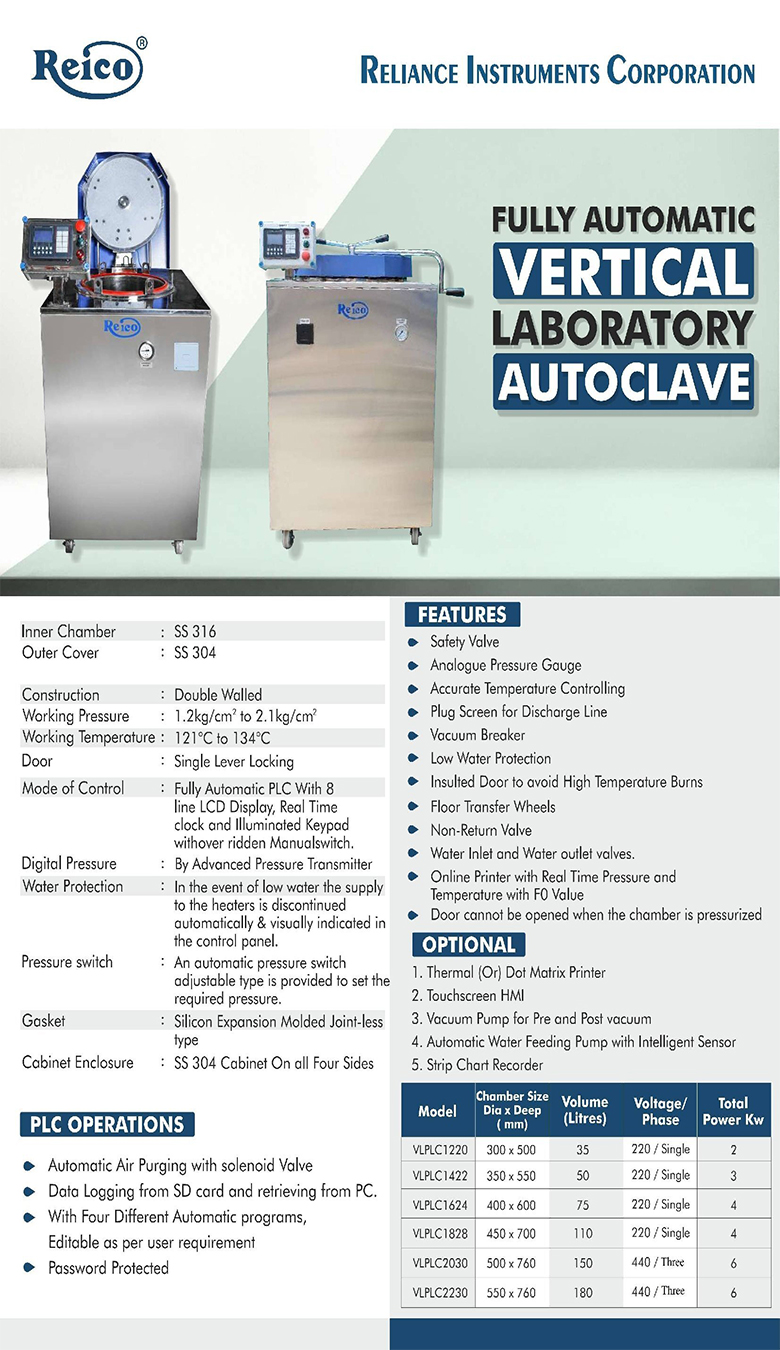

Autoclave is an important part of microbiology laboratory and hospital. Depending upon sterilization test requirements; an autoclave machine comes in different temperature and pressure ranges, various sizes, dimensions and designs.

Vertical Autoclave Manufacturers in Coimbatore

A vertical autoclave can be referred to as a 'top loading autoclave', as the chamber door pivots upwards to allow access to the chamber beneath. Astell produces four different sizes of this type ranging from 63 litres in capacity up to 135 litres.

Vertical Autoclave Manufacturers in Mumbai

Autoclaves use steam heat to kill any microbial life that may be present on a contaminated load. A load — also known as goods — is considered sterile once it has undergone a full sterilization cycle.

Vertical Autoclave Manufacturers in Kolkata

An autoclave is a machine that uses steam under pressure to kill harmful bacteria, viruses, fungi, and spores on items that are placed inside a pressure vessel. The items are heated to an appropriate sterilization temperature for a given amount of time.

Vertical Autoclave Manufacturers in Delhi

Vertical autoclaves are also known as top loading sterilizers that come in cylindrical shape. These are widely used in hospitals, Operation Theater (OT), microbiology laboratory for sterilization of various medial and cultures.

High Pressure Autoclave Manufacturers in Chennai

High-pressure autoclaves are designed for pressures far above 100 bar. The material properties must therefore be able to withstand such a load. All connections, i.e. valves, measuring devices and closures, are specially designed for applications under the influence of high pressure and temperature.

High Pressure Autoclave Manufacturers in Bangalore

The autoclaving process takes advantage of the phenomenon that the boiling point of water (or steam) increases when it is under high pressure. It is performed in a machine known as the Autoclave where high pressure is applied with a recommended temperature of 250°F (121°C) for 15-20 minutes to sterilize the equipment.

High Pressure Autoclave Manufacturers in Hyderabad

Essentially an autoclave is a pressure cooker that uses steam under pressure as its sterilizing agent. The increase in pressure (above atmospheric pressure) enables steam to reach higher temperatures. The extra pressure brings the boiling temperature of water higher. In fact, around 20°C higher.

High Pressure Autoclave Manufacturers in Mumbai

What is autoclave sterilization? The simplest explanation is that it is a highly effective method of sterilizing and disinfecting objects through the use of heat — in the form of steam — plus pressure and time.

High Pressure Autoclave Manufacturers in Kolkata

An autoclave is a device that works on the principle of moist heat sterilisation, wherein saturated steam is generated under pressure in order to kill microorganisms such as bacteria, viruses, and even heat-resistant endospores from various types of instruments.

High Pressure Autoclave Manufacturers in Delhi

Autoclaving is the most popular method of lab sterilization. This process uses pressurized steam to heat the item that requires sterilization. Autoclaving is an incredibly effective procedure. It will effectively kill all microbes, spores and viruses.

Horizontal Autoclave Manufacturers in Chennai

The two basic types of steam sterilizers (autoclaves) are the gravity displacement autoclave and the high-speed prevacuum sterilizer.

Horizontal Autoclave Manufacturers in Tamil Nadu

4 Main Methods of Sterilization | Organisms | Microbiology

Physical Methods: ...

Radiation Method: ...

Ultrasonic Method: ...

Chemical Method:

Horizontal Autoclave Manufacturers in Coimbatore

Autoclave sterilization works by using heat to kill microorganisms such as bacteria and spores. The heat is delivered by pressurized steam. Pressurization allows the steam to reach the high temperatures that are required for sterilization.

Horizontal Autoclave Manufacturers in Mumbai

Saturated steam used in sterilization reaches the high temperature of 121℃ or 134℃, which is so hot that when it comes into contact with the load and condenses, it transfers enough heat to kill all the microorganisms on the load. This is one of the reasons why steam is such an effective sterilization agent.

Horizontal Autoclave Manufacturers in Kolkata

A steam steriliser, also known as an 'autoclave', uses saturated steam at 121–132 °C. A typical standard for steam sterilisation is achieved after 15 to 30 minutes under a pressure of 106 kPa (1 atm) once all surfaces have reached a temperature of 121 °C

Horizontal Autoclave Manufacturers in Delhi

Steam is the autoclave's sterilization agent. In our Sterilization Methods series, we explained the physics of steam and why it's ideal for destroying microorganisms such as bacteria and spores.

SS Autoclave Manufacturers in Chennai

Autoclaving is the most effective and reliable means of sterilizing laboratory materials. Autoclaving sterilizes material using saturated steam under pressure (“moist heat”).

SS Autoclave Manufacturers in Bangalore

Can 304 stainless steel be autoclaved?

Steam Autoclave Features : Chambers are solid 304 or 316 stainless steel. Orbital welding is available upon request. Sterilizer piping is 304 or 316 stainless steel and the valves are 316 stainless steel. Sanitary piping, fittings and valves are available upon request.

SS Autoclave Manufacturers in Hyderabad

Autoclaving is the most effective and reliable means of sterilizing laboratory materials. Autoclaving sterilizes material using saturated steam under pressure (“moist heat”). Due to the use of pressure, steam and high temperatures, there is significant risk for injury, so it's important for individuals to be properly trained on operational procedures.

SS Autoclave Manufacturers in Mumbai

Autoclaves may be used to sterilize equipment/products prior to use in an experiment or to render items non-infectious prior to disposal. The University of Iowa’s Biohazard Waste Guidelines states that cultures, plates, and vials containing pathogenic organisms must be autoclaved prior to disposal.

SS Autoclave Manufacturers in Kolkata

The reason for autoclaving infectious waste is that it must be handled several times during transport; proper containment and treatment at the source reduces the potential for an accidental exposure. The necessary treatment to achieve sterility will vary in relation to the volume of material treated, its contamination level, moisture content and other factors.

SS Autoclave Manufacturers in Delhi

Every autoclave and sterilizer should be inspected and serviced on a regular basis. This will help ensure the equipment is functioning properly.

Stainless Steel Autoclave Manufacturers in Chennai

Each unit should have a standard operating procedure written in sufficient detail to ensure that operators will use the equipment properly; controls vary between brands, with each having unique loading characteristics, load-sizing requirements, and cycle setting and types. Principal Investigators and/or lab managers should ensure users are properly trained on the autoclave in use.

Stainless Steel Autoclave Manufacturers in Bangalore

Units should be tested regularly with a commercial preparation containing Geobacillus stearothermophilus spores (a biological indicator), in particular, any unit in a BSL3 facility.

Stainless Steel Autoclave Manufacturers in Hyderabad

Tape indicators (autoclave tape) with heat sensitive, chemical indicators should be used in every autoclave load. Note: the indicators only verify that the autoclave has reached normal operating temperatures; they do not indicate that the contents were heated for the appropriate length of time or at the proper pressure. Therefore, tape indicators cannot be used to prove organisms are actually killed during an autoclave run.

Stainless Steel Autoclave Manufacturers in Mumbai

High density wastes or materials that insulate the agents from heat and steam penetration are not suitable for steam sterilization. Items that are covered with dirt or film require additional retention times. The importance of properly cleaning items to be sterilized cannot be over emphasized.

Stainless Steel Autoclave Manufacturers in Kolkata

Keep detailed records on biological tests, recording thermometers, and service work performed on the unit.

Stainless Steel Autoclave Manufacturers in Delhi

Place all autoclaved infectious waste into red biohazard bags for disposal. Autoclaved waste can cause odors, the use of autoclave deodorizers may assist if there is a general problem in the area.